At G&G we operate a Quality Management System with policies and procedures to ensure the services we offer are of the highest quality standard.

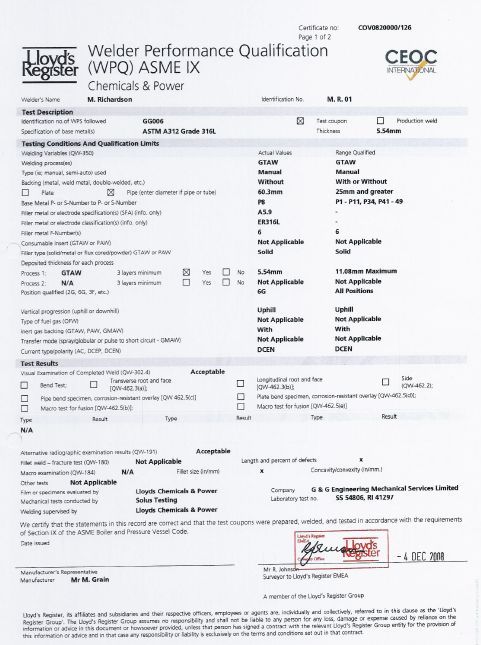

Our welders are certified to international standards and follow client specific and/or international manufacturing procedures. We also work with clients to facilitate inspection hold points during the manufacture or refurbishment process.

During equipment assembly, G&G perform visual, dimensional, alignment and/or operational inspection as required.

During equipment installation and commissioning, G&G may perform torque, vibration, noise and/or power consumption testing in accordance with the customer requirements.

In such cases, on completion, we will provide a full report outlining the results of the condition monitoring and operational checks.